MLCC

One of the Most Widely Used

and Fastest-Growing Passive Components

One of the Most Widely Used

and Fastest-Growing Passive Components

What makes MLCC (Multilayer Ceramic Capacitors) stand out?

Let's explore together.

Let's explore together.

01 What is MLCC?

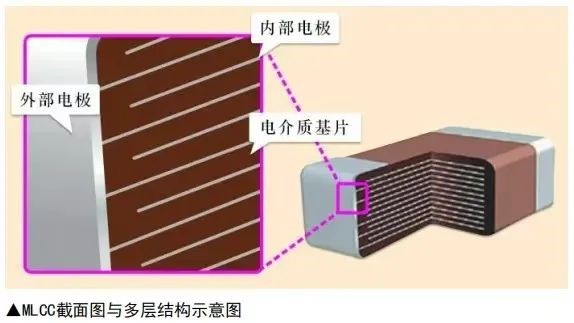

MLCC, or Multilayer Ceramic Capacitors, as the name suggests, uses ceramic as the dielectric material in a multilayer stacked structure.

More specifically, it consists of ceramic dielectric layers with printed electrodes (internal electrodes) stacked in a staggered arrangement. These layers are then sintered at high temperatures to form a ceramic chip. Metal layers (external electrodes) are added to both ends of the chip, resulting in a structure similar to a monolithic capacitor, hence the name monolithic capacitor.

MLCCs are primarily used in oscillation, coupling, filtering, and bypass circuits for various electronic devices. They were first developed by a U.S. company in the 1960s, quickly gaining industrial traction in Japan, where the technology advanced rapidly, and they continue to dominate the global MLCC market today.

02 Small Size, Big Applications

When it comes to the industry status of MLCCs, despite their small size—sometimes as small as a grain of rice—MLCCs have a vast range of applications. With an annual market consumption exceeding trillions of units, the potential is enormous. It is truly the "rice of the electronics industry."

NO.1: The Top Performer in the Capacitor Market

In the capacitor market, ceramic capacitors, with their smaller size, larger voltage range, and lower cost, account for about 50% of the market. Among ceramic capacitors, MLCCs take up over 90% of the market share due to their low equivalent series resistance (ESR), high voltage and temperature resistance, long lifespan, and wide capacitance range.

NO.2: Strong Demand, Continuous Potential

As one of the most widely used passive surface-mount components in electronic devices, MLCCs are applied in automotive, communications, consumer electronics, industrial, healthcare, and military sectors. The demand for MLCCs is especially high in consumer electronics, which accounts for 70% of the market share.

As electronic devices become increasingly complex and intelligent, the demand for MLCCs continues to rise. In rapidly developing fields such as automotive electronics and AI servers, the application potential of MLCCs is being deeply explored. For example, smartphones typically use around 1200 to 1500 MLCCs, while laptops use about 1000. In AI servers, the number of MLCCs required is usually between 3000 and 4000, and the monetary value of MLCCs used in AI servers can be more than four times that of regular servers. Interestingly, a single electric vehicle can require between 10,000 and 15,000 MLCCs.

03 Unique Advantages of MLCCs

NO.1: Wide Capacitance Range

By using multilayer stacking technology, MLCCs provide much larger capacitance compared to single-layer capacitors.

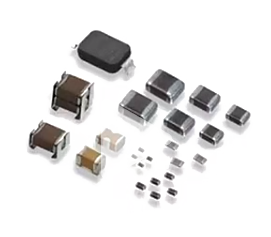

NO.2: Ultra-Compact Size

With the ongoing trend of making smartphones, tablets, and wearable devices thinner and lighter, the demand for smaller capacitors is increasing. Currently, MLCC sizes are shrinking from 0805, 0603, 0402 to 0201, 01005, allowing for ultra-compact, ultra-thin capacitors that enable high-density installation in electronic devices.

NO.3: Low ESR

MLCCs typically have ESR values of only a few milliohms to tens of milliohms, much lower than other types of capacitors. The lower the ESR, the less heat is dissipated during operation, allowing more energy to be used for the operation of electronic devices rather than wasted as heat, thus improving operational efficiency and extending the lifespan of the capacitor.

NO.4: High Rated Voltage

Thanks to the high-temperature sintering process of ceramic materials, MLCCs have a dense structure, offering excellent voltage resistance and a wide voltage range that meets the requirements of various circuit standards.

NO.5: Good High-Frequency Characteristics

The quality of materials used in MLCCs ensures that they have excellent low resistance and impedance at all frequency bands, making them ideal for high-frequency circuits.

NO.6: No Polarity

Since MLCCs are non-polarized, they are more convenient for assembly and use.

04 Industry Landscape and Development Trends

NO.1: Industry Landscape

Global MLCC manufacturers can be categorized into three tiers. The first tier consists of major Japanese and South Korean manufacturers, the second tier includes Taiwanese companies, and the third tier is composed of Chinese mainland manufacturers. Japanese companies hold 56% of the market share and produce small-sized, high-capacity products, while Chinese mainland manufacturers account for 6%, mainly producing medium to large-sized, low-capacity products.

Although domestic companies still lag behind international giants in terms of production capacity and technology, China’s MLCC industry chain is relatively complete, with domestic companies involved in both production equipment and materials.

NO.2: Development Trends

With the rapid development of the global electronics industry, MLCCs, as fundamental electronic components, are advancing at an impressive speed. The variety of MLCCs continues to grow, their size continues to shrink, their performance improves, and technology progresses. Materials are constantly being updated, and lightweight, compact products are becoming standardized and universal, with applications gradually expanding from consumer electronics to other sectors.

This is MLCC

standing out with its outstanding performance

and wide applications.

It truly deserves the title of

"rice of the electronics industry."

standing out with its outstanding performance

and wide applications.

It truly deserves the title of

"rice of the electronics industry."